A pre-trip inspection is essential for ensuring safety and compliance, especially for Class A vehicles. This checklist helps drivers systematically evaluate their truck before hitting the road, covering critical areas like brakes, tires, and lights. Regular inspections prevent potential hazards and ensure compliance with legal requirements, making it a vital tool for both experienced drivers and those preparing for CDL tests.

Importance of Pre-Trip Inspections

Pre-trip inspections are crucial for ensuring the safety and roadworthiness of Class A vehicles. They help identify potential issues before they lead to breakdowns or accidents, protecting both the driver and other road users. Conducting regular inspections also promotes compliance with state and federal regulations, avoiding potential fines or penalties. Additionally, pre-trip checks can prevent costly repairs by addressing minor problems early. This practice fosters a culture of safety and responsibility, which is essential for professional drivers. By systematically evaluating the vehicle, drivers can ensure optimal performance and reduce the risk of mechanical failures during operation. Ultimately, pre-trip inspections are a cornerstone of safe and efficient commercial driving practices.

Overview of Class A Vehicles

Class A vehicles are the largest and most complex category of commercial motor vehicles (CMVs). They typically include tractor-trailers, big rigs, and other heavy-duty trucks with a gross vehicle weight rating (GVWR) exceeding 26,000 pounds. These vehicles require a high level of skill and knowledge to operate safely and efficiently. Class A vehicles are commonly used for long-haul transportation, carrying large volumes of goods across long distances. Their size and weight demand a thorough pre-trip inspection to ensure all systems are functioning properly. This includes checking brakes, tires, lights, and fluid levels, among other critical components. Proper maintenance and inspection of Class A vehicles are essential to prevent accidents and ensure compliance with regulations. Their role in the transportation industry makes them a vital part of the supply chain, emphasizing the need for meticulous inspection practices.

Legal Requirements for Pre-Trip Inspections

Pre-trip inspections are mandated by state and federal regulations to ensure vehicle safety. Inspection stickers are required for road tests, and compliance is critical for CDL certification and legal operation.

State and Federal Regulations

Pre-trip inspections for Class A vehicles are governed by both state and federal regulations to ensure road safety and compliance. The Federal Motor Carrier Safety Administration (FMCSA) mandates that all commercial vehicles, including Class A, undergo regular inspections. States also enforce specific requirements, which may include annual inspections or more frequent checks. Inspection stickers are often required to verify compliance, and failure to display them can result in penalties. Drivers must adhere to these regulations to avoid fines, delays, or even disqualification from operating commercially. Additionally, the Commercial Driver’s License (CDL) pre-trip inspection test evaluates a driver’s ability to identify and report vehicle defects, ensuring they meet federal and state standards. Compliance with these regulations is critical for legal operation and safety on the road.

Necessity of Inspection Stickers

Inspection stickers are a critical component of compliance for Class A vehicles, serving as proof that a vehicle has passed a required inspection. They are mandated by both state and federal regulations to ensure that all commercial vehicles meet safety standards. Without a valid inspection sticker, a vehicle may be denied a road test or even prohibited from operating on public roads. Inspection stickers provide a visual confirmation that the vehicle has been thoroughly checked for defects and is safe to operate. They are often tied to the results of a pre-trip inspection, reinforcing the importance of conducting these checks diligently. Failure to display a current sticker can result in fines, penalties, or other enforcement actions, making them an essential aspect of maintaining compliance and safety in commercial driving.

Pre-Trip Inspection Checklist for Class A Vehicles

A comprehensive checklist for Class A vehicles ensures safety and compliance by covering key areas like brakes, tires, lights, fluids, and coupling systems, promoting thorough evaluations before every trip.

Outside Checks

Outside checks are crucial for identifying potential issues before hitting the road; Start by inspecting the license plate to ensure it is clean and visible. Check the overall body condition for any damage or dents that could affect safety. Verify that the windshield is clean and free of cracks, and ensure all lights (headlights, brake lights, turn signals) are functioning properly. Inspect the tires for proper inflation, tread depth, and signs of wear. Check the wheels for tightness and ensure the brake components are secure. Examine the suspension for any leaks or damage. Lastly, inspect the coupling devices to ensure they are securely connected. These checks help prevent accidents and ensure compliance with safety regulations.

Under the Hood Checks

Under the hood checks are vital for ensuring the engine and its components are in good working condition. Start by checking the oil level to ensure it is within the recommended range. Verify the coolant level and look for any signs of leakage in the coolant hoses. Check the power steering fluid and brake fluid levels, ensuring they are at the appropriate levels. Inspect the air dryer for proper function and check the alternator belt for cracks or wear. Look for any leaks under the engine compartment and ensure there are no signs of damage to the belts or hoses. Finally, perform an air gauge test to ensure the air pressure does not drop more than 4psi in one minute. These checks help prevent mechanical failures and ensure safe operation of the vehicle.

Inside the Cab Checks

Inside the cab checks are crucial for ensuring the driver’s environment is safe and functional. Begin by checking the parking brake to ensure it is fully engaged. Verify that all seat belts are in good condition and properly secured. Adjust the mirrors (rearview, side, and convex) for clear visibility. Check the steering wheel for proper alignment and ensure there is no excessive play. Test all gauges on the dashboard to ensure they are functioning correctly and within normal ranges. Ensure all switches for lights, signals, and other systems are operational. Test the horn to confirm it works. Check the wipers and defroster to ensure proper visibility. Inspect the emergency equipment, such as the fire extinguisher and first aid kit, to ensure they are present and accessible. These checks ensure the driver has a safe and functional workspace.

Coupling and Trailer Checks

Coupling and trailer checks are essential to ensure safe and secure connections between the tractor and trailer. Begin by inspecting the fifth wheel and kingpin to ensure they are properly engaged and free from damage. Check the locking mechanism to confirm it is securely fastened. Inspect the trailer brakes and ensure they are functioning correctly. Verify that all air lines and electrical connections between the tractor and trailer are securely attached and not damaged. Test the trailer lights, including brake lights, turn signals, and marker lights, to ensure they are operational. Check the trailer tires for proper inflation and signs of wear. Finally, ensure all safety devices, such as trailer supports, are in place and functioning. These checks ensure the trailer is safely and securely connected to the tractor.

Step-by-Step Inspection Process

The step-by-step inspection process involves checking for Leaks, Leans, and Lights, followed by a detailed examination of the brake system, tires, and fluid levels to ensure the vehicle is road-ready and safe.

Leaks, Leans, and Lights

Begin by inspecting for Leaks under the engine and engine compartment. Check for any signs of fluid leakage, such as oil, coolant, or brake fluid, which could indicate potential issues. Next, ensure the vehicle is not Leaning to one side, as this may suggest uneven weight distribution or suspension problems. Finally, verify that all Lights, including headlights, brake lights, turn signals, and hazard lights, are functioning properly. This step is crucial for safety and visibility on the road. Use a checklist to systematically evaluate each component. Additionally, ensure the low air warning system is operational and that air gauges do not exceed the allowed pressure drop. This methodical approach helps identify and address issues before they escalate, ensuring a safe and compliant journey. Always refer to the official guidelines for specific inspection criteria. Proper documentation of findings is essential for maintenance and regulatory purposes. Regular practice of this process enhances efficiency and thoroughness, making it a cornerstone of professional driving habits. By following these steps, drivers can significantly reduce the risk of mechanical failures and ensure compliance with safety standards. This foundational inspection process is vital for both experienced drivers and those preparing for their CDL test, as it underscores the importance of vehicle maintenance and roadworthiness.

Brake System Inspection

The brake system inspection is a critical component of the pre-trip process, ensuring the vehicle can stop safely and efficiently. Start by checking for any visible leaks around brake valves, hoses, and connections. Depress and hold the brake pedal to ensure it does not feel spongy or soft, which could indicate air leaks or fluid loss. For Class A vehicles, air gauges should not lose more than 4psi in one minute during this test. Additionally, ensure the low air warning system activates when air pressure drops below a safe level. Listen for any unusual noises or vibrations when applying the brakes. Proper brake function is essential for safety and passing the CDL pre-trip inspection. Any defects found must be documented and repaired before operating the vehicle. This step ensures compliance with safety regulations and prevents potential accidents on the road.

Tire and Wheel Inspection

The tire and wheel inspection ensures proper vehicle safety and handling. Begin by visually inspecting all tires for signs of wear, such as uneven tread, bulges, or cuts. Check tire pressure using a gauge, ensuring it matches the manufacturer’s recommended levels. Test each tire by thumping it to verify it is inflated correctly. Examine the wheels for loose or missing lug nuts and ensure they are tightened securely. Look for any signs of damage or rust on the rims. Properly inflated and maintained tires improve fuel efficiency, handling, and safety. Any defects, such as low tread or uneven wear, must be documented and addressed before operating the vehicle. This step is crucial for preventing blowouts and maintaining control on the road, ensuring compliance with safety standards and regulations. Regular inspections help extend tire life and reduce maintenance costs. Always refer to the vehicle’s specifications for accurate pressure levels.

Fluid Levels Check

Checking fluid levels is a critical part of the pre-trip inspection. Start by examining the engine oil level using the dipstick; it should be within the recommended range. Next, inspect the coolant level in the reservoir, ensuring it meets the minimum mark. Check the transmission fluid level, typically found via a dipstick, and verify it is at the appropriate level. Power steering fluid and brake fluid levels should also be checked, ensuring they are not low. Look for any signs of leaks around the reservoirs or lines. If any fluid level is below the recommended level, address it before driving. Proper fluid levels are essential for maintaining engine performance, preventing overheating, and ensuring the safe operation of the vehicle. Always refer to the vehicle’s manual for specific guidelines, and never skip this step to avoid mechanical failures. Regular monitoring helps extend the vehicle’s lifespan and prevents costly repairs. Ensure all caps are securely tightened after inspection. This step is vital for ensuring the vehicle runs smoothly and safely throughout the journey. Keep track of any changes in fluid levels to identify potential issues early. By maintaining proper fluid levels, drivers can avoid breakdowns and ensure compliance with safety standards. This inspection is a cornerstone of pre-trip safety protocols and should never be overlooked. Always carry extra fluids if needed, based on the vehicle’s specifications. Proper fluid management is key to efficient and safe vehicle operation. Regular checks help prevent unexpected issues and ensure the vehicle is roadworthy. Remember, fluid levels are a critical indicator of the vehicle’s health, and neglecting them can lead to serious mechanical failures. Always prioritize this step in your pre-trip routine to guarantee a safe and trouble-free journey.

Testing and Evaluation

Testing and evaluation involve a thorough review of the pre-trip inspection checklist to ensure all safety standards are met, confirming the vehicle is roadworthy and safe to operate.

CDL Pre-Trip Inspection Test

The CDL pre-trip inspection test evaluates a driver’s ability to identify potential safety issues in a Class A vehicle. During the test, drivers must systematically inspect components such as brakes, tires, lights, and fluids, demonstrating thorough knowledge of safety procedures. The inspection checklist serves as a guide, ensuring no critical areas are overlooked. Drivers are required to explain their findings clearly, showing they can identify defects that would render the vehicle unsafe. Failure to pass this test can result in not obtaining a CDL, emphasizing the importance of preparation and understanding the inspection process. Proper documentation and adherence to the checklist are crucial for success.

Common Defects to Look For

During a pre-trip inspection, it’s crucial to identify common defects that could pose safety risks. Leaks, such as oil or coolant drips, should be checked under the engine. Tires must be inspected for proper inflation, tread depth, and signs of wear. Brake systems should be tested for air leaks and proper function, ensuring the brake pedal doesn’t drop too low. Lights, including headlights, brake lights, and turn signals, must be operational. The vehicle should not lean to one side, indicating potential suspension issues. Fluid levels, such as oil, coolant, and brake fluid, should be within recommended ranges. Coupling and trailer connections must be secure to prevent detachment during transit. Addressing these defects early ensures safety and compliance with regulations, avoiding potential failures during the trip or inspection.

Consequences of Failed Inspections

Failing a pre-trip inspection can lead to serious consequences, including being placed out of service, which halts operations until issues are resolved; Drivers and carriers may face fines or penalties for non-compliance with safety regulations. Repeat offenses can result in higher insurance rates and damage to a carrier’s safety rating. Additionally, faulty equipment increases the risk of accidents, endangering lives and potentially leading to legal liability. Delays caused by failed inspections can disrupt schedules and impact delivery timelines. Furthermore, consistent inspection failures may prompt regulatory audits, intensifying scrutiny on the carrier’s maintenance practices. It’s crucial to address defects promptly to avoid these outcomes and ensure safe, compliant operations.

Handling Inspection Defects

Identify and document defects found during inspections, ensuring repairs are made promptly. Maintain detailed records of issues and their resolution to comply with safety standards and regulations effectively.

Documenting Issues

Documenting issues found during pre-trip inspections is crucial for maintaining safety and compliance. Use the checklist to note any defects or malfunctions, such as leaks, worn tires, or faulty lights. Record the severity of each issue and whether it requires immediate attention or can be addressed later. Include details like the date, vehicle identification number, and mileage for accurate tracking. This documentation serves as a legal record and helps in planning repairs. Drivers must sign off on the inspection report to confirm completion. Proper documentation also aids in communicating problems to maintenance teams, ensuring timely fixes. Keeping detailed records fosters accountability and helps prevent overlooked issues, ultimately enhancing road safety and regulatory compliance. Accurate and thorough documentation is a cornerstone of responsible vehicle maintenance.

Repair and Maintenance Procedures

Once issues are identified during the pre-trip inspection, prompt repair and maintenance are essential to ensure roadworthiness. Address critical defects immediately, such as brake failures or fluid leaks, to prevent safety risks. Non-critical issues should be documented and scheduled for repair at the earliest convenience. Use the checklist to track progress and verify that all necessary fixes are completed. Repairs must comply with federal and state regulations, and only qualified technicians should perform complex tasks. After repairs, conduct a follow-up inspection to confirm that all issues have been resolved. Proper maintenance extends the vehicle’s lifespan and reduces the likelihood of breakdowns. Always reference the vehicle’s maintenance manual for specific procedures. Regular servicing ensures compliance with safety standards and avoids potential penalties. Communication between drivers and maintenance teams is vital for efficient repairs and continuous vehicle operation. A well-maintained vehicle is safer and more reliable on the road;

Best Practices for Conducting Inspections

Adopt a systematic approach when performing inspections to ensure nothing is overlooked. Use checklists to stay organized and focused, prioritizing critical areas like tires and brakes for safety.

Time Management Tips

Effective time management is crucial for conducting thorough pre-trip inspections without delays. Start by creating a routine or checklist to follow, ensuring no critical areas are overlooked. Prioritize inspecting high-priority components like tires, brakes, and lights first, as these are vital for safety. Minimize distractions by focusing solely on the inspection process. Utilize technology, such as mobile apps, to streamline and track your progress. Always allocate a set amount of time for each section of the inspection to avoid spending too long on one area. Additionally, perform visual checks for obvious issues before diving into detailed examinations. By staying organized and proactive, you can complete the inspection efficiently while maintaining attention to detail. Remember, the goal is to balance thoroughness with time efficiency to ensure safety and compliance.

Using Technology for Efficiency

Technology has revolutionized the pre-trip inspection process, making it more efficient and less time-consuming. Digital checklists and mobile apps allow drivers to systematically track inspections, ensuring no step is missed. Many apps provide real-time guidance, step-by-step instructions, and customizable templates tailored for Class A vehicles. Some platforms integrate with vehicle systems to automatically detect issues like low tire pressure or faulty brakes. Additionally, tools like barcode scanners and RFID tags can quickly verify equipment status, reducing manual effort. Cloud-based solutions enable fleets to store inspection records securely, simplifying compliance reporting. By leveraging these tools, drivers can complete inspections faster while maintaining accuracy and compliance. Technology not only streamlines the process but also enhances overall safety and accountability, making it an indispensable resource for modern trucking operations.

Training and Resources

Online courses and printable guides are available for mastering pre-trip inspections. These resources provide detailed checklists and step-by-step instructions, ensuring compliance with safety and legal standards effectively.

Online Courses for Pre-Trip Inspections

Online courses provide comprehensive training on pre-trip inspections for Class A vehicles, ensuring drivers understand safety protocols and legal requirements. These courses cover detailed checklists, step-by-step inspection processes, and tips for identifying potential issues. Topics include leaks, leans, and lights, as well as brake systems, tire inspections, and fluid level checks. Many platforms offer interactive modules, videos, and quizzes to enhance learning. Drivers can access these courses anytime, making it convenient to prepare for CDL tests or refresh their knowledge. By completing these programs, drivers can improve their inspection skills, reduce the risk of accidents, and ensure compliance with federal and state regulations. These resources are essential for both new and experienced drivers aiming to maintain safety and efficiency on the road.

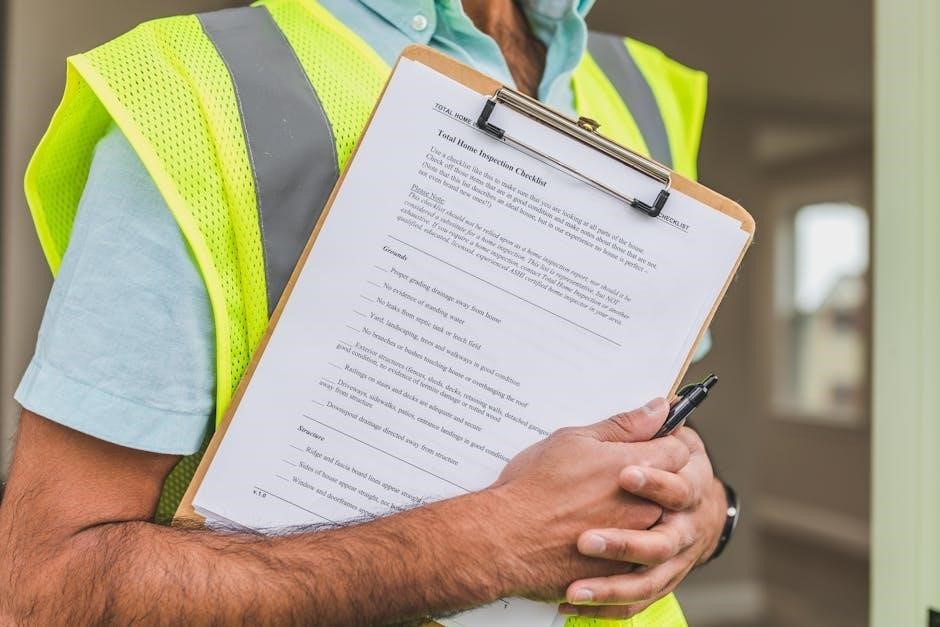

Printable Checklists and Guides

Printable checklists and guides are invaluable tools for conducting thorough pre-trip inspections of Class A vehicles. These resources provide a structured format to ensure no critical components are overlooked. Designed for both experienced drivers and CDL applicants, they often include sections for outside checks, under-the-hood inspections, and cab evaluations. Many guides are available in PDF format, making them easy to download and use offline. They also emphasize the importance of inspection stickers and compliance with legal requirements. By following these checklists, drivers can streamline the inspection process, reduce errors, and ensure their vehicle is roadworthy. Additionally, printable guides often include visual aids and step-by-step instructions, making them user-friendly and accessible for all skill levels. These resources are essential for maintaining safety, efficiency, and regulatory compliance during pre-trip inspections.

A well-executed pre-trip inspection ensures safety, prevents potential hazards, and guarantees compliance with regulations. By following detailed checklists, drivers can confidently operate Class A vehicles, fostering a culture of responsibility and adherence to safety standards.

A pre-trip inspection for Class A vehicles is crucial for ensuring safety and compliance with legal standards. This process involves checking critical components such as tires, brakes, lights, and fluid levels to identify potential issues before they lead to accidents. The inspection must be thorough, following a detailed checklist to avoid oversights. Regular inspections not only prevent mechanical failures but also help drivers comply with state and federal regulations, avoiding penalties. Additionally, a well-executed pre-trip inspection is a key requirement for passing the CDL test, demonstrating a driver’s ability to operate a vehicle safely. By adhering to these practices, drivers can significantly reduce risks and contribute to a safer driving environment. Consistency and attention to detail are essential for building a strong safety culture in the trucking industry.

Final Thoughts on Safety and Compliance

Pre-trip inspections are a cornerstone of road safety and regulatory compliance for Class A vehicles. By systematically evaluating critical components, drivers ensure their vehicle is roadworthy, reducing the risk of accidents and mechanical failures. Compliance with state and federal regulations is non-negotiable, as failure to meet standards can result in penalties or even operational shutdowns. A thorough pre-trip inspection fosters a culture of safety, accountability, and professionalism. It not only protects the driver and other road users but also safeguards the integrity of the trucking industry. Regular inspections demonstrate a commitment to maintaining high standards, ensuring that every journey is safer and more efficient. Ultimately, prioritizing safety and compliance through pre-trip inspections is essential for responsible and successful trucking operations.